What Is a Waterproofing Membrane?

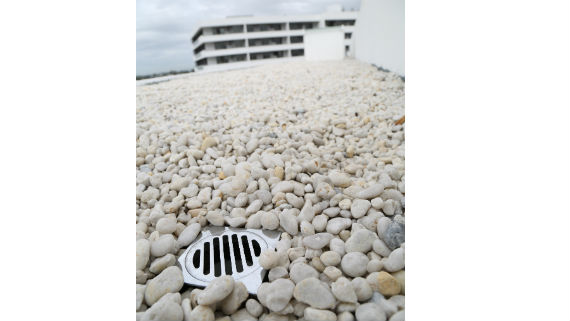

A waterproofing membrane is a tinny layer of waterproof material applied to a fixed surface. As this layer is continuous, it prevents water from passing through it. Waterproofing membranes can be laid out in different ways. For instance, waterproofing membrane can be applied under tiles and above the structural slab of a flat terrace. This way, water does not reach the structural slab. Also, over a filler material, we apply the membrane and tiles, which should be sloped at a slight angle to ensure that water flows into drains and sumps. However, water should not accumulate over the tiles in the form of puddles. If puddles develop over the tiles, water will eventually penetrate the slab over time. Hence, it is essential to make sure that water puddles do not occur.

A waterproofing membrane comprises thin sheets of waterproof material. Most of these sheets are between 2 and 4 mm thick. There are generally two types of membranes:

- Liquid applied membranes

- Sheet-based membranes

The waterproofing membrane must be flexible, sturdy, elastic, and tear-resistant. A membrane with these properties can stretch and cover cracks. These properties also allow the membrane to move with the building structure. Also, the membrane should be UV stable for protection against the sun’s rays. Last but not least, a flexible membrane can adopt the shape of the surface it is laid over.

Sheet-Based Waterproofing Membranes

As the name implies, these membranes exist in the form of rolls. These are unrolled and laid out over any surface. The bituminous waterproofing membrane is the best common sheet-based membranes. It can be attached to a firm surface using a hot tar-based adhesive.

A tar-based adhesive is also used to make joints within adjacent membranes. A waterproof joint is formed by overlapping these sheets by around 100 mm or 4 inches. A hot air gun may be used to join some membranes by melting them and then putting them on the previously laid sheets.

Joints made between sheets (made from this type of membrane) should be perfect so that there is no leakage.

Composite and PVC membranes are other types of sheet-based membranes. Composite membranes consist of a fabric base to provide superior strength and resistance against wear and tear. Also, a chemical coating the fabric offers improved resistance against wear and tear.

These membranes have consistent quality since they are produced in factories (except joints).

Liquid Applied Waterproofing Membranes

These membranes have a liquid form, which is brushed or sprayed to a surface. The liquid is then allowed to cure so that the development of a joint-free and seamless membrane can take place. A simple way to enhance the membrane’s thickness is to add more chemical liquid.

As the application procedure is quick, contractors try to finish the job in one day to avoid cold joints. However, if the area to be covered is large, the procedure may be completed over multiple days. Installing a new membrane layer over the previous one can help avoid cold joints. Consequently, the chemical will attach to itself.

Since these membranes are free from joints, they are better than sheet-based membranes. However, their application requires more considerable expertise to get the right thickness. If the membrane is too thin, it can rupture easily. The membrane must firmly adhere to the surface.

If there is a need to apply a concrete layer over it, the membrane texture should be made rough through a process called sand broadcasting. Sand broadcasting entails casting a thin layer of sand on the membrane. If the sand is still wet or not cured yet, it will stick to the membrane. As a result, the sand presents the ideal rough surface for the particular concrete application.

Properties of Waterproofing Membranes

You can select the right membrane by checking the presence of the following features:

UV Stability

In the case of excessive or prolonged sun exposure, the membrane should be resistant to UV rays. As a result, UV stability helps prevent the membrane from deteriorating as a result of sun exposure.

Elongation

Elongation (expressed as a percentage) indicates how much the material will stretch.

For instance, a 150 per cent elongation implies that the membrane will stretch one-and-a-half times its original length (when pulled).

High elongation is necessary where movement is significant. For example, it is essential for buildings made from steel – a flexible material. Similarly, high-rise buildings also move significantly.

Breathability

Proper waterproofing comes with a significant disadvantage. If water manages to seep into the membrane, it will be trapped and will not be able to escape. Breathable membranes can resolve this issue.

Breathable membranes release the trapped water as vapour. Therefore, the best membrane is not only waterproof, but it should also allow water vapour to pass through. With breathable membranes, there is no risk of water accumulation.

Tear Resistance

Although many membranes have excellent elongation, they are vulnerable to tearing.

To get an idea of tear resistance, take the membrane in your hand, and stretch it. High-quality membranes will not tear, despite the application of a relatively high force.

Abrasion Resistance

Abrasion resistance refers to the capability of a membrane to resist wear and tear. Abrasion occurs during the construction period. It may happen due to workers walking over the membrane, scraping hard objects, dropping items over it. If a membrane is soft with low abrasion resistance, it is likely to get damaged easily.

Chemical Stability

The membrane should be chemically inert towards its environment, especially when exposed to rainwater and soil.

Contact us today for further information about waterproofing membranes.